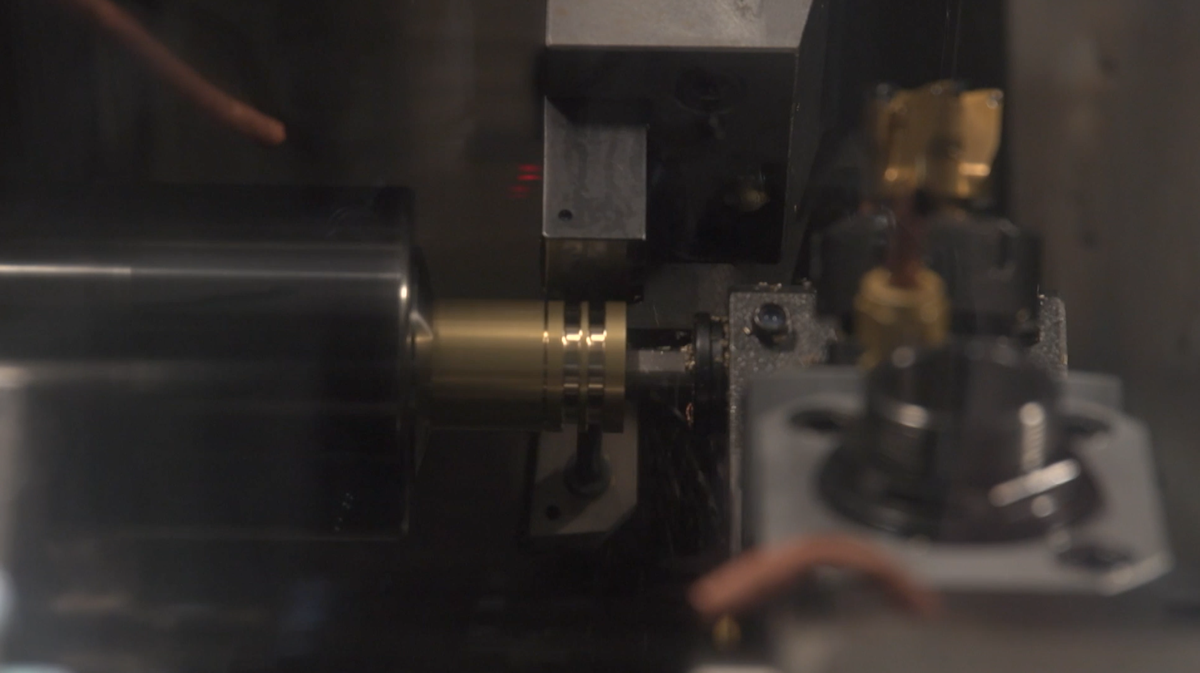

PRECISION CNC MACHINING SERVICES

Meeting your machining expectations requires deep expertise, a range of advanced equipment and a history of successfully applying best practices. At Specialty Mfg we take this very seriously and adhere to rigorous machining standards. We are uniquely qualified to evaluate the details of your project and work with you from initial design consulting through testing and on-time shipping.

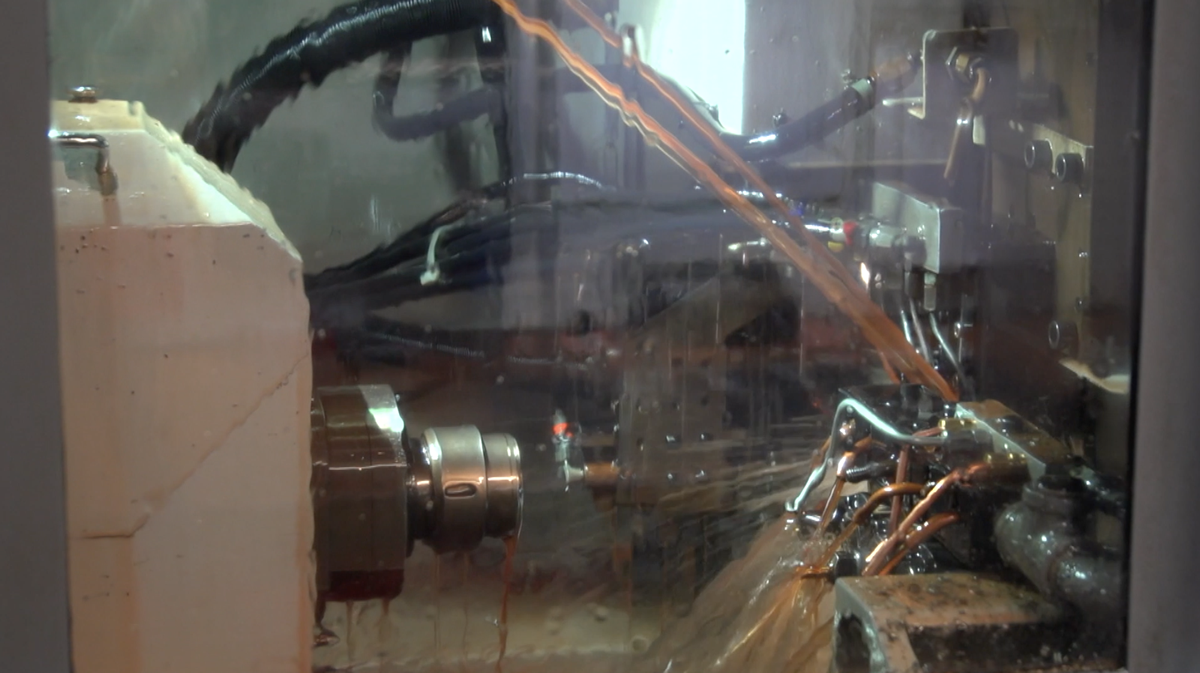

With our array of state-of-the-art CNC and mechanical equipment, we have the right machines and personnel to run your cnc machining parts economically and to your precise specifications.

CNC Milling & Turning • Swiss Turning • Automatic Screw Machines • Value Added Engineering

Materials

We are well versed in most machinable materials. We have one of the largest inventories of brass in the Midwest. Our machinists are highly skilled, and our facility supports all secondary operations necessary to complete your project. We commonly work with these materials:

|

|

Secondary Operations

To ensure proper surface finish and to offer the best possible lead times we have in-house capabilities to provide:

- Cleaning

- Vibratory deburring

- Passivation

- Harperizing

- Assembly

Engineering

We welcome the opportunity to assist our customers in product design. Our engineers will work with you to ensure maximum design for manufacturing and assembly (DFMA). We also have in-house SLA model capabilities. Our engineers work with the following software:

- AutoCAD

- SolidWorks

- Feature CAM

- Pro E

- Part Maker

- Inventor

Services Offered By Qualified Vendors

- Plating

- Abrasive blasting

- Ultra-sonic cleaning

- Thermo-deburring

- Electro-polishing

- Laser marking

- Heat treating

Specialty Integrated Services is an integral part of The Specialty Mfg. Co., one of North America’s oldest and most respected manufacturers. For over a century, The Specialty Mfg. Co. has been a leader in manufacturing innovative products. The Specialty Mfg. Co has honed its expertise and processes since 1900. The Company produces nearly all components necessary for our broad line of world class metal and plastic valves. This expertise is a valuable resource for other manufacturers interested in partnering with the best!