PLASTIC INJECTION MOLDING

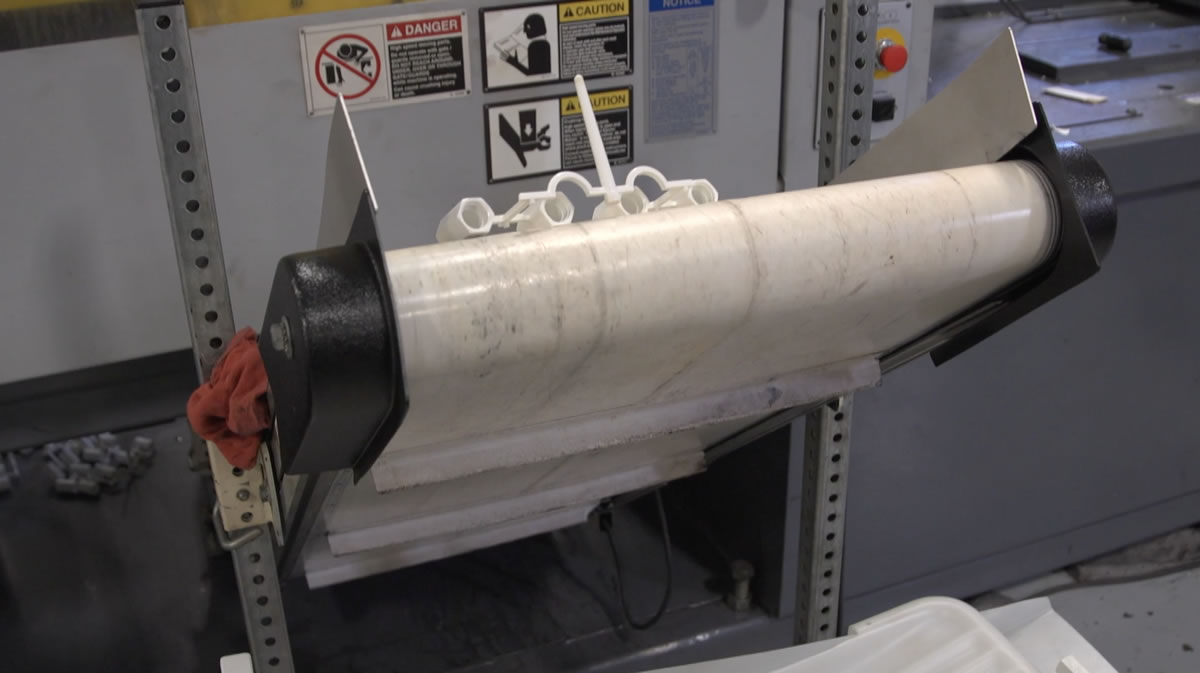

Plastic injection molding is a core competency of ours where we produce millions of components and finished goods annually. These parts are used in a vast array of industrial and consumer finished assemblies. Since 1986 we have invested in the state-of-the-art presses and tooling processes to not only be price competitive but also offer the services other contract manufacturers simply can’t or won’t do. Our quality standards and know-how are among the industry’s leaders.

Because of our vertically integrated approach, Specialty Integrated Services can supply anything from a single low volume molded part, to a high-volume sub-assembly components. And because your schedule is the most important, we offer short lead times and flexible programmed delivery in the quantities you need. Specialty Integrated Services also provides a full range of services including engineering and secondary operations required to complete your projects on time.

Specialty Integrated Services welcomes the opportunity to assist our customers in product design. Our engineers will work with you to ensure maximum design quality for manufacturing and assembly. Excellent customer service and satisfaction are hallmarks of our company and foundational to our business success. Our commitment to customer service will ensure your success, as well.

All of our presses are hydraulic, horizontal toggle machines with the exception of one vertical press used primarily for insert molding. We run both manual and automatic unscrewing molds as well as insert molds. Threaded inserts, bushings or other metallic inserts can be supplied by our in-house precision machining department. All of our presses can be equipped with driers and/or chillers as necessary to run your parts.

We run standard engineering grade materials, including filled and unfilled. While we normally source the resin, we are happy to use customer supplied material when required. Our facility has all of the necessary driers and chillers to ensure that your parts are made to the highest possible dimensional and cosmetic quality standards.

Materials commonly run include:

- Nylon

- Acetal

- PVC

- Polypropylene

- Polyethylene

- Polystyrene

- Polyester

- Polycarbonate

- Santoprene and other TPE’s

- And others as needed

Specialty Integrated Services is an integral part of The Specialty Mfg. Co., one of North America’s oldest and most respected manufacturers. For over a century, The Specialty Mfg. Co. has been a leader in manufacturing innovative products. Specialty Integrated Services has honed its expertise and processes since 1900. The Company produces nearly all components necessary for our broad line of world class metal and plastic valves. This expertise is a valuable resource for other manufacturers interested in partnering with the best!