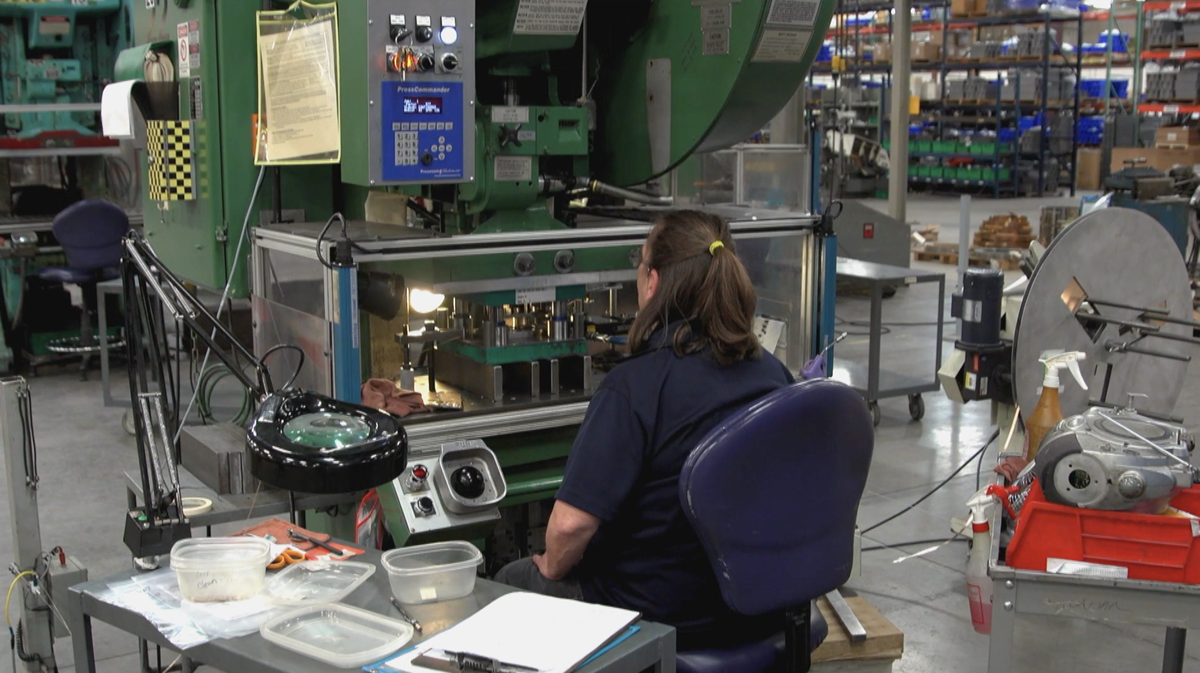

METAL STAMPING

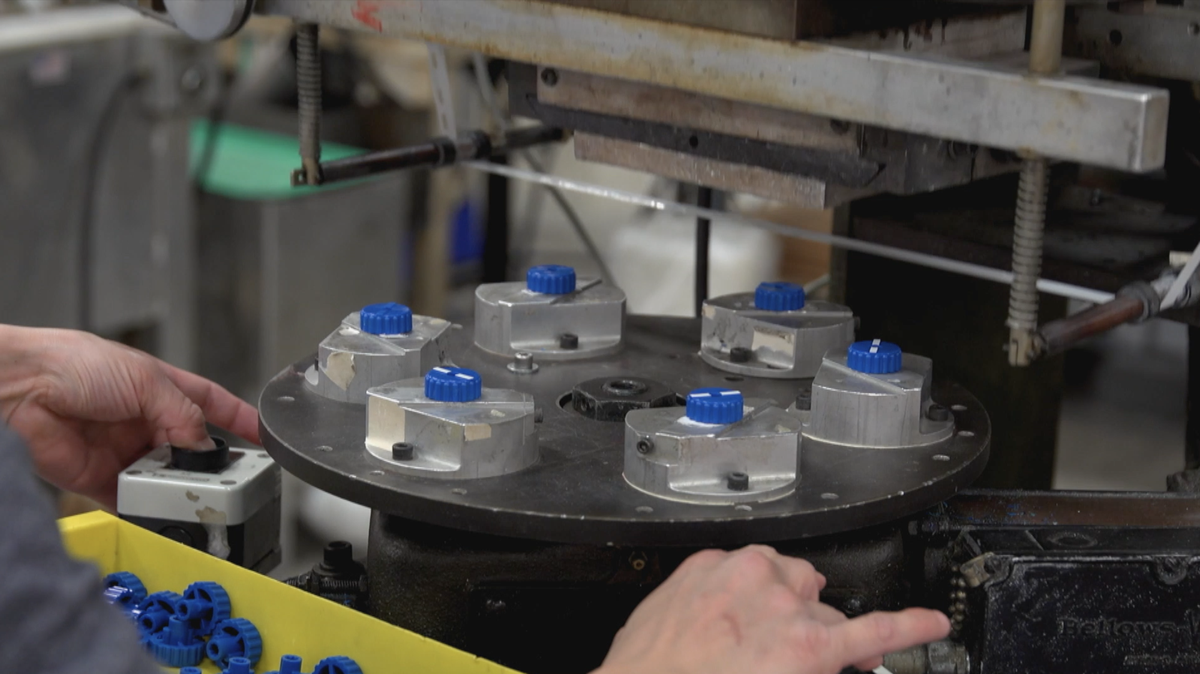

Your stamping project requires precision and technical know-how. We specialize in progressive and compound tools to turn out close-tolerance, complex parts, delivered to the exact specifications your project requires. Our record of 98% on-time delivery means that the sub assembly components you need are available when you need them. Decades of experience with compound dies and progressive tooling have made Specialty the choice for a wide range of industries around the world.

Specialty Integrated Services also welcomes the opportunity to collaborate with customers in product design. World class customer service is a hallmark of our company and foundational to our business success.

Since 1900, The Specialty Mfg. Co. has been a leader in manufacturing innovative products. Specialty Integrated Services embodies our vertically integrated contract manufacturing services that bring flexibility and efficiency to the management of your project. We do the things that our competitors can’t or simply won’t do.

If your project requires, small-to-medium sized metal parts in quantities of tens to hundreds of thousands or more, Specialty Stamping is the most efficient and cost-effective precision metal stamping in Minnesota.

Specialty Integrated Services is ready and willing to take on your toughest projects. Lean on our long manufacturing legacy to deliver your project on-time with impeccable results.

When you’re ready to get started, give us a call at 651-653-0599 or request a quote!