WIRE EDM

Specialty Integrated Services Wire EDM division specializes in low to medium/high volume EDM cutting of precision parts. Wire EDM services provide an extremely precise method of cutting electrically conductive materials with a very high degree of precision–and with minimal or no tooling required. Thin material can be stacked to yield hundreds of parts at one time, making this method a competitive alternative to the more costly process of stamping tooling. Specialty Integrated Services is experienced with a wide variety of materials (see list below) and can work with customer supplied materials for custom designed projects. To provide the best possible customer lead times, supplementary operations in-house and specialized services from trusted vendor partners are available to ensure our Wire EDM products fully meet your requirements.

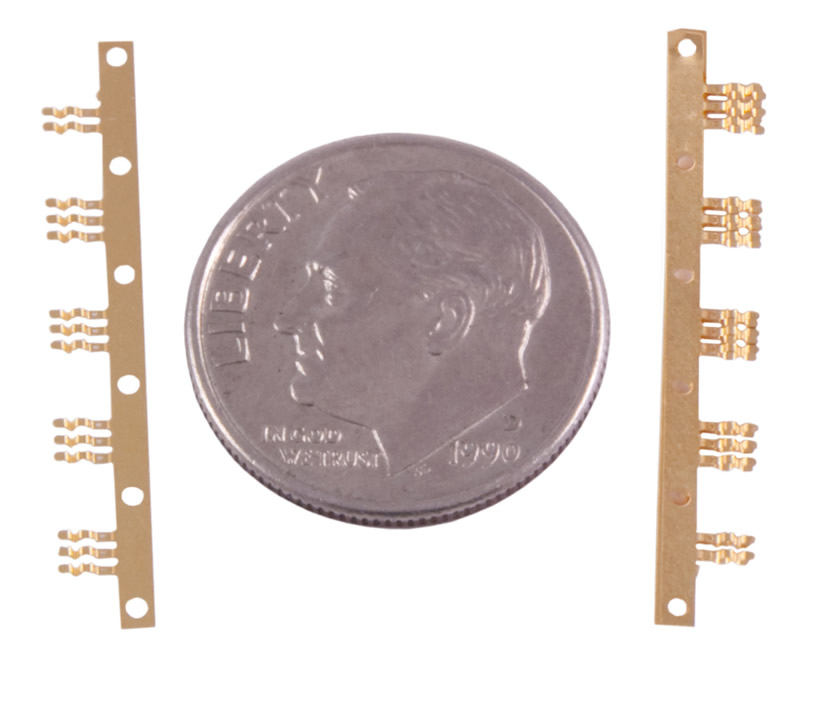

- Test socket contacts

- Wire sizes 0.002″-0.012″

- Tolerances: tolerances as tight as 0.0002″ can be held depending on material and part design.

- Materials from 0.001″ to 10″ thick

- Miniature and micro-miniature parts

- Wide variety of alloys, including precious metals (as long as they are conductive)

- Able to hold very tight tolerances

- High volume contacts to tight tolerances

- Minimal or no tooling charges

- Precious metals

- Excellent for pre-hardened materials

- Quick turnaround prototypes

We are experienced with a wide variety of materials and will work with customer supplied materials when needed. Thicknesses from 0.001″-10.0″ thick.

We commonly run:

- Aluminum

- Brass

- Bronze

- Copper Alloys

- Steel

- Stainless steel, austenitic and martensitic

- Exotics including platinum, gold, others

- Tool Steels

We welcome the opportunity to assist our customers in product design. Our engineers will work with you to ensure maximum design quality for manufacturing and assembly. Excellent customer service and satisfaction are hallmarks of our company and foundational to our business success. Our commitment to customer service will ensure your continued business success, as well. The proof is in the final product.

Specialty Integrated Services is an integral part of The Specialty Mfg. Co., one of North America’s oldest and most respected manufacturers. For over a century, The Specialty Mfg. Co. has been a leader in manufacturing innovative products. Specialty Integrated Services has honed its expertise and processes since 1900. The Company produces nearly all components necessary for our broad line of world class metal and plastic valves. This expertise is a valuable resource for other manufacturers interested in partnering with the best!